Operations

Operations Management

All businesses – whether services, manufacturing, distribution or retail – face operational issues. The quest to delight customers is common across sectors, by providing products and services at the right place, the right time, in the right way and at the right price. Business customers and individual consumers continue to raise the bar in terms of their service expectations, driven in part by the nearly-instant fulfillment now offered by leading ecommerce merchants. Higher expectations, dramatic changes in technology and online access to global sources of supply require companies to constantly improve operations. Service delivery has become a differentiator in many industries. As a result, we are often asked to assess operations with an eye to radical reinvention of processes, to meet evolving customer needs, upgrade responsiveness and resilience, and streamline to remove unnecessary steps and costs.

The kinds of issues we address include:

- Customer requirements: What are the needs of specific customer segments? What service would we need to deliver, to differentiate our offer? What will customers pay for?

- Current bottlenecks: How are operations currently thwarting the efficient fulfillment of customer needs?

How are processes actually performed – as opposed to ‘on paper’?

- Performance drivers: What are the main drivers of cost and service levels?

- Radical reinvention: What does the end-state look like, in terms of service delivery to the customer?

- Roadmap: How can we best proceed, in stages, towards the end-state goal, while realizing savings and other benefits that fund the longer-term transformation?

- Process redesign: How should critical processes be re-imagined to deliver enhanced performance?

- Automation: Which process steps can be automated, freeing up resources to devote to higher value-added work?

- Technology: What tools are needed to manage improved processes?

- People: What new skill sets are required to implement more sophisticated, analytically-driven operations?

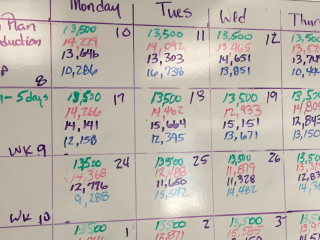

- Performance management: How could a digital dashboard help drive continuous improvement?

Our capabilities include:

- Customer preferences, using conjoint analysis and other advanced techniques

- Current state assessment

- Process and results benchmarking

- Process improvement

- Technology evaluation, in support of recommended processes

- Organizational design and skills evaluation

- Digital dashboards for operational performance

Supply Chain Management

Today’s best “supply chains,” the networks of product and information flows and value creation that tie together demand and supply, are increasingly longer, wider and more complex as both product and service companies seek to reach global customers and leverage global resources. Customers, empowered with more information and decision tools, are demanding more personalized products and services, made on demand, and ordered and delivered in ways that minimize time and maximize convenience between purchase decision and product benefit realization. Effective supply chain management in this environment can have significant impacts on the customer experience and company financials, balancing flexibility, risks and rewards.

Our project teams quickly hone in on the presenting issues and opportunities:

- Customer needs: What are the characteristics of the supply chain can drive customer behaviors and enhance the customer experience?

- Sourcing: How best to manage insourcing and outsourcing? Re-shoring and right-shoring? Strategic sourcing and procurement?

- Flow paths and facility locations: How are the forward and reverse products flows best routed? How many and where should facilities be located? What value-adding operations should take place in each location?

- Inventory deployment: Where and how should inventory be deployed? When should ownership change?

- Transport: What are best transport modes & routing? Carriers? Collaboration partners?

- Business process insource vs. outsource: What are the company’s core competencies? Who can best perform the function? At what level of risk and rewards?

- Technology: What are the best technologies and IT business applications to get the best out of the overall supply chain and within each functional area?

- Adaptability & risk mitigation: How flexible is the supply chain? What “stresses” will put the supply chain at risk? Are contingency plans robust?

- Globalization: Are there opportunities to more effectively manage globally and leverage capabilities off-shore while effectively managing risk?

Services:

- Supply chain strategy and planning

- Network optimization

- Benchmarking and performance improvement

- Sales & operations planning

- Organizational effectiveness and design

- Business applications technology selection

- Outsourcing assessments and partner selection/contracting support

- Implementation support

Strategic Sourcing

Strategic sourcing decisions and procurement execution represent significant opportunities in many companies, because for many companies purchased inputs make up the majority of product cost. Moreover, poor service from suppliers can have huge detrimental impacts on new product introductions and supply chain cost and service performance. Hence, many best-practice companies put the procurement function at the same table as marketing and finance.

Leading sourcing executives and chief procurement officers now must tackle complex issues that require a multidisciplinary focus. Supply management goes beyond leveraging supplier spend and volume consolidation to address broader issues, such as supply chain integration, outsourcing, and joint technology and product development with suppliers.

Our project teams quickly hone in on the presenting issues and opportunities:

- Spend base: How much is being spent? For what? Where? Which suppliers? How does this compare to benchmarks?

- Commodity rationalization: Can unique or custom items be re-specified to simplify the buy and increase commonality across products and company divisions?

- Supplier base: What is each supplier’s share of the spend? Performance levels? Unique value adds?

- Supplier collaboration: Can suppliers add more value? When, where and how?

- Processes & skills: Does the organization have a robust strategic sourcing function and executional procurement processes and the right skills?

- Contracting: Are SLAs well specified? What is the best mix of long-term vs. short and spot agreements? Risks and rewards?

- Performance scorecarding: What mechanisms are deployed to measure and track supplier performance and costs? How are the results used to improve service and cost performance?

- Decision support: What technologies and tools will enhance performance?

New Harbor offers deep sourcing and procurement execution capabilities:

- Strategic sourcing

- Competitive cost and service benchmarking

- Procurement integration and organization

- “Right sourcing”: shared services, outsourcing and offshoring

- Process improvement and performance measurement

- Organizational effectiveness and training

New Harbor staff has addressed a broad range of supply chain management and strategic sourcing questions for industry leaders, mid-sized companies seeking the next engine of growth, start-ups, and private equity and venture capital firms.